Remember

Concrete Surface Profile CSP and Liquid Membrane Installation cannot be treated separately but form a single system.

Concrete Surface Profile CSP and Liquid Membrane Installation cannot be treated separately but form a single system.

Also Read Liquid Membranes Installation Guide

Every tested and compliant liquid membrane in the market is designed to perform as per what it is intended to achieve. However, the product represents a smaller portion of the system; the latter terminology is what designers, and waterproofing contractors must use instead. Why?

Liquid membranes are not used as stand-alone products, but form part of a system, which is affected by the weather, the substrate condition (Concrete Profile), thickness, terminations, transition over obstacles, chemicals, abrasion, etc.

Best CSP for Liquid Membranes and tolerances

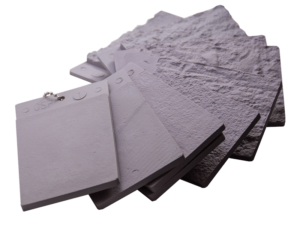

Therefore, the Concrete Surface Profile CSP specification, developed by the International Concrete Repair Institute (ICRI) in 2013, is neither a choice nor a guess, but logically and experimentally chosen. There are 10 categories named based on the average distance from the peaks on the surface to the valleys. Here is the logic behind it:

- The tolerances of the liquid membrane thickness are not covered. However, TfNSW recommends 10% for bridge decks, which are usually precast pre-stressed elements where the surface finish is controlled during the segments’ production in the precast yard. See reference https://standards.transport.nsw.gov.au/_entity/annotation/2dfef953-060b-ee11-8f6d-002248e416de.

- CSP depths are classed between 1 – 10 and their depths are digitally measured as per ASTM D8271. Most liquid membrane suppliers recommend CSP 3, which translates to an average depth of 0.3mm for the substrate for optimal performance (11 +/-2 Mils = 0.28 +/- 0.05mm).

- So, with a target thickness of 1.5mm, you can go 1.2-1.8mm. However, the minimum/maximum specified DFT must be > 20% of the readings, and the minimum/maximum DFT must be > 80% of what is specified (20% is equivalent to 0.3mm). As a result, to match the CSP 3, the membrane installation tolerances must be 20% and not 10%.

Summary

In summary, the high and low points of the substrate (Based on the surface CSP) will play a crucial role in the membrane thickness locally, hence the overall performance of the liquid membrane system. Therefore, it is advisable to allow enough time to repair all the high and low points beyond the tolerances to achieve the best results.

Applicators must rely on something measurable, which in my opinion 20% (for a 1.5mm thick, the deviation would be around 0.3mm). Depending on the solids in the membrane, the thickness calculation must be carried out for the Wet Film Thickness WFT with at least 80% of the overall area passing the test.

Photos credit:

Neogaurd, KTA Gage, and Kryton

Written by Hacène Baleh 28/08/2024

To receive new notification of new educational posts:

Follow Hacène Baleh on LinkedIn

Follow Baleh Consulting on LinkedIn